OOPS! You forgot to upload swfobject.js ! You must upload this file for your form to work.

Overclockers are trying to improve the thermodynamic properties of Skylake processors

![]()

|

xtreview is your : Video card - cpu - memory - Hard drive - power supply unit source |

|

|||

|

|

||||

Recommended : Free unlimited image hosting with image editor

Recommended : Free unlimited image hosting with image editor

|

POSTER: computer news || OVERCLOCKERS ARE TRYING TO IMPROVE THE THERMODYNAMIC PROPERTIES OF SKYLAKE PROCESSORS |

DATE:2016-03-05 |

|

|

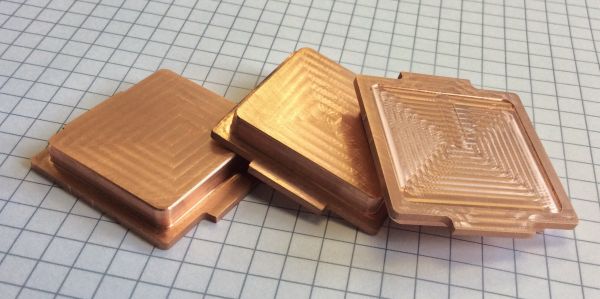

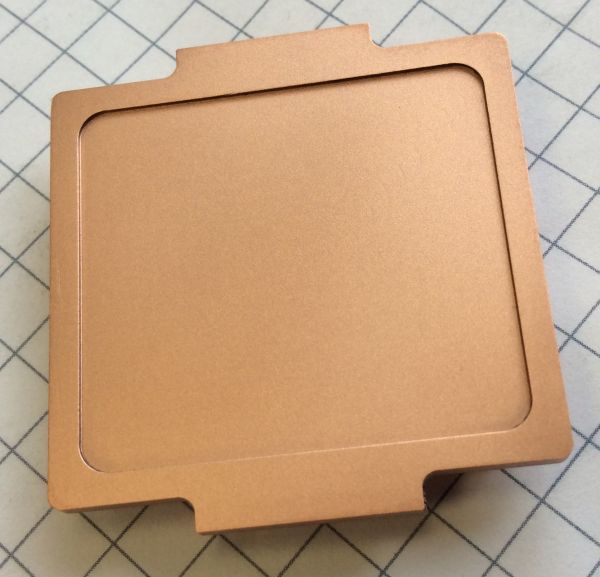

Growing and growing dissatisfaction with the behavior of Intel Skylake processors during overclocking experiments, involves the use of liquid nitrogen and special tanks. Fixing these tanks to the motherboard usually involves a wide range of clamping force. As is known, printed Skylake processor board has a modest thickness and properties of regular thermal interface processor under the hood is not that good. Thermal Paste processor under the lid in contact directly with the crystal tends to expand when heated and contract when cooled. Together with mechanical action exerted on the processor tank mounting system for liquid nitrogen, like vibrations during extreme overclocking contribute to the deterioration of contact between the processor lid thermal grease under it and the processor chip. The existence of the problem may indicate a characteristic crack during overclocking using liquid nitrogen.  The famous German enthusiast Der8auer suggested colleagues to experiment with changing the distance between the processor lid and crystal. For this batch it produced metal gaskets 0.1 mm thick, which must be placed between the processor circuit board and the cover. By increasing the number of plates, it is possible to increase the gap between the cover and the crystal.   The panelists noted that the silver cap would be more effective, although it would have cost a few hundred euros per share.  Related Products : | ||

|

|

||

|

xtreview is your : Video card - cpu - memory - Hard drive - power supply unit source |

|

|

|

|

||

|

Xtreview Support  N-Post:xxxx Xtreview Support        |

OVERCLOCKERS ARE TRYING TO IMPROVE THE THERMODYNAMIC PROPERTIES OF SKYLAKE PROCESSORS |

| Please Feel Free to write any Comment; Thanks  |

We are looking for copper coolers on NVIDIA Volta computing accelerators (2017-09-08)

The older Skylake processors with a free multiplier are removed from production (2017-09-07)

AMD Bristol Ridge processors are also available in American retail (2017-09-07)

The characteristics of the mobile chip MediaTek Helio P40 are known (2017-09-06)

Asustek increases its share in the segment of expensive motherboards (2017-09-05)

Some stores are already daring to sell Radeon RX Vega 64 (2017-08-28)

Not more than half of Germans and Americans are ready to use robotic vehicles (2017-08-28)

Video card manufacturers are preparing for the September deficit AMD Radeon RX Vega (2017-08-26)

In the line of Dell Alienware gaming systems, more affordable models will appear (2017-08-26)

Radeon RX Vega red kits are not available on the official website (2017-08-25)

We are looking at Noctua coolers for AMD Ryzen Threadripper (2017-08-25)

Gigabyte prepares non-standard video cards Radeon RX Vega series Aorus (2017-08-23)

Almost 70 percents of the memory lines are in the destruction zone (2017-08-19)

The creator of one of the fastest GeForce GTX 1080 Ti shared the secrets of overclocking (2017-08-15)

THE SHARES OF NVIDIA CONTINUE TO FALL IN PRICE (2017-08-14)

Observers are encouraged to focus on the capabilities of Radeon RX Vega 56 (2017-08-11)

Tesla prepares to begin testing electric trucks with autopilot (2017-08-10)

The share price of NVIDIA shares rose in anticipation of quarter results announcement (2017-08-08)

Lithium processing companies are ready to develop due to long-term contracts (2017-08-08)

Chinese investors are still interested in assets Imagination Technologies (2017-08-07)

![]()

To figure out your best laptops .Welcome to XTreview.com. Here u can find a complete computer hardware guide and laptop rating .More than 500 reviews of modern PC to understand the basic architecture

7600gt review

7600gt is the middle card range.

We already benchmarked this video card and found that ...

geforce 8800gtx and 8800gts

geforce 8800gtx and 8800gts  Xtreview software download Section

Xtreview software download Section  AMD TURION 64 X2 REVIEW

AMD TURION 64 X2 REVIEW  INTEL PENTIUM D 920 , INTEL PENTIUM D 930

INTEL PENTIUM D 920 , INTEL PENTIUM D 930  6800XT REVIEW

6800XT REVIEW  computer hardware REVIEW

computer hardware REVIEW  INTEL CONROE CORE DUO 2 REVIEW VS AMD AM2

INTEL CONROE CORE DUO 2 REVIEW VS AMD AM2  INTEL PENTIUM D 805 INTEL D805

INTEL PENTIUM D 805 INTEL D805  Free desktop wallpaper

Free desktop wallpaper  online fighting game

online fighting game  Xtreview price comparison center

Xtreview price comparison center Lastest 15 Reviews

Rss Feeds

Last News

- The new version of GPU-Z finally kills the belief in the miracle of Vega transformation

- The motherboard manufacturer confirms the characteristics of the processors Coffee Lake

- We are looking for copper coolers on NVIDIA Volta computing accelerators

- Unofficially about Intels plans to release 300-series chipset

- The Japanese representation of AMD offered monetary compensation to the first buyers of Ryzen Threadripper

- This year will not be released more than 45 million motherboards

- TSMC denies the presentation of charges from the antimonopoly authorities

- Radeon RX Vega 64 at frequencies 1802-1000 MHz updated the record GPUPI 1B

- AMD itself would like to believe that mobile processors Ryzen have already been released

- AMD Vega 20 will find application in accelerating computations

- Pre-orders for new iPhone start next week

- Radeon RX Vega 57, 58 and 59: the wonders of transformation

- ASML starts commercial delivery of EUV-scanners

- The older Skylake processors with a free multiplier are removed from production

- Meizu will release Android-smartphone based on Helio P40

- AMD Bristol Ridge processors are also available in American retail

- The fate of Toshiba Memory can be solved to the next environment

- duo GeForce GTX 1080 Ti in GPUPI 1B at frequencies of 2480-10320 MHz

- New Kentsfield overclocking record up to 5204 MHz

- Lenovo released Android-smartphone K8

HALO 3 HALO 3 - Final Fight!

PREY Prey is something you don t often see anymore: a totally unigue shooter experience.

computer news computer parts review Old Forum Downloads New Forum Login Join Articles terms Hardware blog Sitemap Get Freebies