OOPS! You forgot to upload swfobject.js ! You must upload this file for your form to work.

Laser can be printed out

![]()

|

xtreview is your : Video card - cpu - memory - Hard drive - power supply unit source |

|

|||

|

|

||||

Recommended : Free unlimited image hosting with image editor

Recommended : Free unlimited image hosting with image editor

|

POSTER: computer news || LASER CAN BE PRINTED OUT |

DATE:2012-09-28 |

|

|

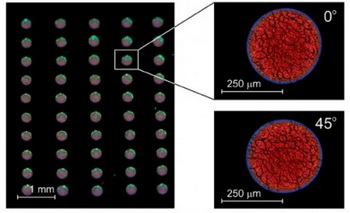

Manufacture of lasers to date involves the use of complex technical processes. However, associate reported about a special way of working with liquid crystals, designed to greatly simplify it. These crystals are similar to those used in LCD displays, but the spiral structure of these molecules can act as an optical resonator cavity. Thus, under certain conditions, they gain the ability to optical excitation, generating a laser.  Early experiments such liquid crystals placed in thin gap between the two glass plates. A special polymer coating on the glass crystals aligns the molecules, and eventually received, scientists LCD laser. Such a method is bad need to comply with sterility and limitations in the choice of substrate - glass or silicon. Experts from Cambridge greatly simplify the process by creating a technology of applying a liquid crystal using a special printing equipment. Now it is possible without any problems to build arrays of lasers of different colors, virtually on any surface. The invention has been patented and its commercial implementation will deal with a subsidiary of the University of Cambridge - Cambridge Enterprise.

Related Products : | ||

|

|

||

|

xtreview is your : Video card - cpu - memory - Hard drive - power supply unit source |

|

|

|

|

||

|

Xtreview Support  N-Post:xxxx Xtreview Support        |

LASER CAN BE PRINTED OUT |

| Please Feel Free to write any Comment; Thanks  |

ASML starts commercial delivery of EUV-scanners (2017-09-07)

AMD Bristol Ridge processors are also available in American retail (2017-09-07)

The fate of Toshiba Memory can be solved to the next environment (2017-09-07)

Ilon Mask believes that the third world war can begin artificial intelligence (2017-09-05)

Not more than half of Germans and Americans are ready to use robotic vehicles (2017-08-28)

The decision on the transaction between WDC and Toshiba can be made on August 31 (2017-08-27)

These days AMD can tell about the Vega successor (2017-08-22)

GlobalFoundries has become the worlds second largest manufacturer, which can produce solutions like AMD Vega (2017-08-17)

SMARTPHONES OF THE FUTURE CAN work WITHOUT TRADITIONAL BATTERIES (2017-08-14)

The external case with the Thunderbolt 3 interface can accept up to three drives with PCI Express interface (2017-08-08)

AMD explains, in what conditions Radeon RX Vega can overclock to 1.7 GHz (2017-08-03)

Sixty-three thousand orders for Tesla Model 3 were canceled (2017-08-03)

A dual-processor version of Vega can be offered by one of AMDs partners (2017-07-31)

In Steam until the end of the weekend you can play for free in Call of Duty Infinite Warfare (2017-07-28)

Manufacturers of smartphones can exacerbate the shortage of components for PC (2017-07-25)

AMD processors Ryzen Threadripper can use the Alphacool water block (2017-07-24)

AMD explained what can be done with all the richness of memory settings in systems based on Ryzen (2017-07-18)

The graphics processor Vega 10 can overclock to 1600 MHz and at low voltages (2017-07-17)

Incident at the Micron factory can contribute to a further rise in prices for memory (2017-07-06)

NVIDIA can soon solve the problem of pascal overclocking (2017-07-05)

![]()

To figure out your best laptops .Welcome to XTreview.com. Here u can find a complete computer hardware guide and laptop rating .More than 500 reviews of modern PC to understand the basic architecture

7600gt review

7600gt is the middle card range.

We already benchmarked this video card and found that ...

geforce 8800gtx and 8800gts

geforce 8800gtx and 8800gts  Xtreview software download Section

Xtreview software download Section  AMD TURION 64 X2 REVIEW

AMD TURION 64 X2 REVIEW  INTEL PENTIUM D 920 , INTEL PENTIUM D 930

INTEL PENTIUM D 920 , INTEL PENTIUM D 930  6800XT REVIEW

6800XT REVIEW  computer hardware REVIEW

computer hardware REVIEW  INTEL CONROE CORE DUO 2 REVIEW VS AMD AM2

INTEL CONROE CORE DUO 2 REVIEW VS AMD AM2  INTEL PENTIUM D 805 INTEL D805

INTEL PENTIUM D 805 INTEL D805  Free desktop wallpaper

Free desktop wallpaper  online fighting game

online fighting game  Xtreview price comparison center

Xtreview price comparison center Lastest 15 Reviews

Rss Feeds

Last News

- The new version of GPU-Z finally kills the belief in the miracle of Vega transformation

- The motherboard manufacturer confirms the characteristics of the processors Coffee Lake

- We are looking for copper coolers on NVIDIA Volta computing accelerators

- Unofficially about Intels plans to release 300-series chipset

- The Japanese representation of AMD offered monetary compensation to the first buyers of Ryzen Threadripper

- This year will not be released more than 45 million motherboards

- TSMC denies the presentation of charges from the antimonopoly authorities

- Radeon RX Vega 64 at frequencies 1802-1000 MHz updated the record GPUPI 1B

- AMD itself would like to believe that mobile processors Ryzen have already been released

- AMD Vega 20 will find application in accelerating computations

- Pre-orders for new iPhone start next week

- Radeon RX Vega 57, 58 and 59: the wonders of transformation

- ASML starts commercial delivery of EUV-scanners

- The older Skylake processors with a free multiplier are removed from production

- Meizu will release Android-smartphone based on Helio P40

- AMD Bristol Ridge processors are also available in American retail

- The fate of Toshiba Memory can be solved to the next environment

- duo GeForce GTX 1080 Ti in GPUPI 1B at frequencies of 2480-10320 MHz

- New Kentsfield overclocking record up to 5204 MHz

- Lenovo released Android-smartphone K8

HALO 3 HALO 3 - Final Fight!

PREY Prey is something you don t often see anymore: a totally unigue shooter experience.

computer news computer parts review Old Forum Downloads New Forum Login Join Articles terms Hardware blog Sitemap Get Freebies